BRUDER Spielwaren - leaders in production and packaging

BRUDER Spielwaren’s particular strength lies in the innovative force involved in developing and manufacturing new toys with typical BRUDER functionality. BRUDER hosts all stages from idea to production and marketing under one roof at the company’s head office in Fürth, Germany.

Cutting-edge production technology

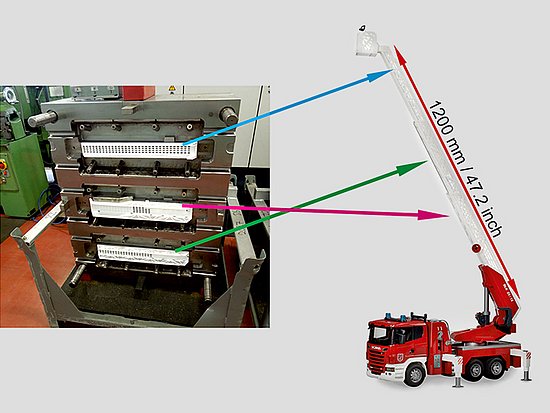

BRUDER toy vehicles are developed and designed using cutting-edge CAD computer programs and 3D design work stations before they are passed on in house to mould making. At this stage, state-of-the-art CNC milling machines are employed to produce mould inserts and assemble individual steel parts to the complete mould.

Sustainably preserving resources

In-house plastic production can start once injection moulds have been put together. The company’s machinery includes around 100 CNC injection moulding machines. Exclusively high-grade plastics just like those used in parts of the automotive industry are applied. Plastic residue is collected and reintroduced to the material cycle as part of a recycling procedure so that we particularly preserve resources and protect the environment.

Ready for future activities

Just like in plastics production we are able to rely on decades of expertise in assembly, making efficient production possible. Thanks to plug-in connections it is possible to employ assembly machines to durably put together parts in only a few stages. In a last step, toy vehicles are “parked” in renowned, appealing BRUDER packaging before they are shipped to more than 70 countries around the world.

The company has been operating a certified energy management system since 2015.

No catches, but always the right choice

Cutting-edge packaging for a number of demands

BRUDER Spielwaren products are packed in high-quality packaging, intended to provide both excellent product protection during transport as well as plenty of product information prior to making the purchase. Each packaging is individually developed, tested and optimised by BRUDER Spielwaren.